Anti icing solution for bridge cables

Bridge Cable Icing Background

Ice formation on bridge cables in cold and high-altitude regions increases their weight, affects their aerodynamic shape, and poses a significant safety hazard when ice melts and falls onto vehicles and pedestrians.

Conventional de-icing technologies both domestically and internationally include manual de-icing, mechanical de-icing, hot air de-icing, and laser de-icing, with manual de-icing being the most commonly used. However, this method is inefficient, costly, dangerous to operate, and often ineffective in complex geographical environments.

Bridge Cable Anti-Icing Technology

Deqian Xincai uses carbon nanotube heating films combined with biomimetic self-cleaning anti-icing fluorosilicone coatings to effectively solve the problem of cable icing during winter, protecting the safety of pedestrians and vehicles.

The carbon nanotube heating film embedded within the bridge cables acts like an "electric blanket," providing heat for de-icing. This solves the issue of heating layers peeling off due to frequent vibrations while the cables remain under tension. The heating film is only 0.5 millimeters thick, does not affect the aerodynamic shape of the cables, and has low energy consumption with an electrical-to-heat conversion efficiency of 99.5%.

The outer surface of the bridge cables is coated with biomimetic self-cleaning anti-icing fluorosilicone coating, which has ultra-hydrophobicity, delayed icing, quick melting, self-cleaning, and excellent aging resistance properties.

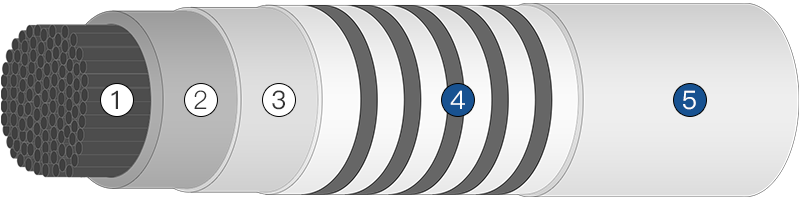

① Steel wire bundle

② Protective sealing layer

③ PE protective sleeve

④ Carbon nanotube heating film

⑤ Biomimetic self-cleaning anti-icing fluorosilicone coating

Features of Bridge Cable Anti-Icing Technology

Ultra-Hydrophobicity

The outer surface of the bridge cables is coated with biomimetic self-cleaning anti-icing fluorosilicone coating, making water droplets unable to stay on the surface, thus preventing icing.

Delayed Icing

Compared to other coatings on the market, the biomimetic self-cleaning anti-icing fluorosilicone coating lowers the nucleation temperature of ice and extends the time it takes for ice to form.

Fast Melting

On the carbon nanotube heating film, the biomimetic self-cleaning anti-icing fluorosilicone coating can achieve rapid ice melting.

Mechanical Properties

- Tensile strength: >10MPa

- Elongation at break: >150%

- Tear strength: >40kN/m

- Wear resistance: <40mg (750g/500r)

Wear Resistance

The biomimetic self-cleaning anti-icing fluorosilicone coating can withstand sand abrasion and UV light exposure, directly affecting the performance of the coating.

Aging Resistance

As the aging time increases, the hydrophobic performance of different coatings decreases, and ice adhesion strength increases. After four to five years of sun exposure and rain, the biomimetic self-cleaning anti-icing fluorosilicone coating maintains good hydrophobicity, ensuring effective anti-icing and easy de-icing performance over a long period.

Low Ice Adhesion Strength

The biomimetic self-cleaning anti-icing fluorosilicone coating contains low-surface-energy materials such as fluoropolymers and organosilicon polymers, which have weak Van der Waals forces with water molecules.

In the early stages of cable icing, it allows ice layers to "slide" on the cable, significantly reducing adhesion between the ice and the cable, making it easier for wind or natural conditions to remove the ice layers and prevent heavy ice buildup.

Performance Testing of Biomimetic Anti-Icing Self-Cleaning Fluorosilicone Coating

| Test Content | Parameters | Remarks |

|---|---|---|

| Water Contact Angle | 90°~152° | |

| Surface Energy | 17.8mN/m | |

| Icing Time | 611 seconds | -20°C |

| Ice Nucleation Temperature | -18.9°C | |

| Ice Adhesion Strength | 32.80kPa | -20°C |

| 2.0kPa | 10°C | |

| Fast Melting, Automatic Sliding Off | 730s | -20°C |

| Roughness Before and After Wear | 0.381μm → 0.522μm | 1500 cycles |

| Ice Adhesion Strength Before and After Wear | 32.80kPa → 27.55kPa | 1500 cycles |

| Water Contact Angle Before and After UV Aging | 102.1° → 89.33° | 288 hours |

| Ice Adhesion Strength Before and After UV Aging | 32.80kPa → 37.39kPa | 288 hours |

| Tensile Strength | ≥10MPa | |

| Elongation at Break | ≥150% | |

| Tear Strength | ≥40kN/m | |

| Wear Resistance | ≤40mg(750g/500r) |

Bridge Cable Anti-Icing Coating Brand Manufacturer

Deqian Xincai is a national brand dedicated to the research, development, production, sales, and integrated painting services of high-performance anti-corrosion coatings. We provide anti-icing materials for bridge cables and biomimetic self-cleaning anti-icing fluorosilicone coatings, and undertake anti-corrosion work for various bridges.

For questions about bridge cable anti-icing technology, anti-icing coating performance for bridge cables, biomimetic self-cleaning anti-icing fluorosilicone coating prices, and bridge cable anti-icing painting package prices, please contact us by phone: 400-680-8502