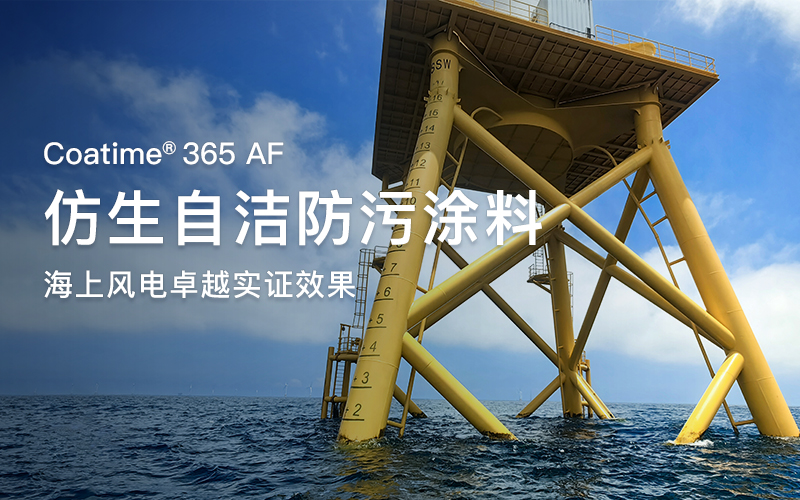

Anti-fouling Material Coating on Wind Power Conductor Frames

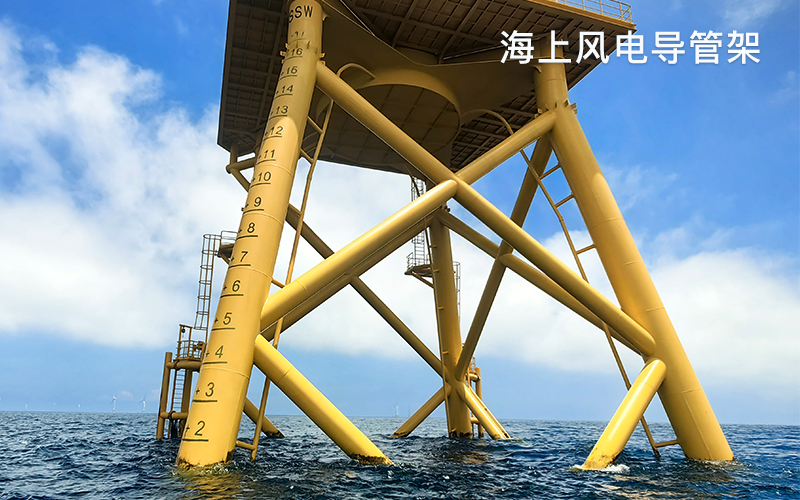

On June 3, 2023, Hunan Deqian New Materials Co., Ltd.'s biomimetic self-cleaning anti-fouling coating material was applied to the conductor frames at a certain offshore wind farm in Yangjiang, marking the first practical application of fouling-release anti-fouling coatings on static marine facilities such as offshore wind power conductor frames.

Follow-up on Anti-fouling Effectiveness After Fourteen Months

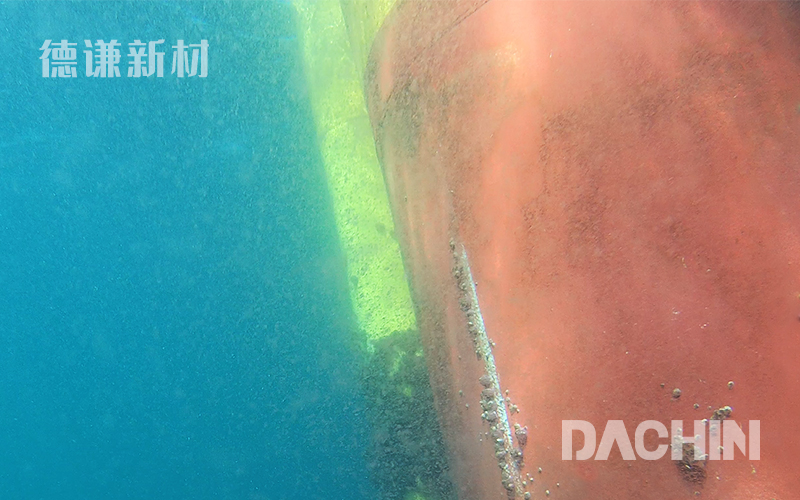

After two summers, the owners and expert teams reviewed the effectiveness of the anti-fouling measures. On August 4, 2024, Deqian Xincai organized a set of underwater photography.

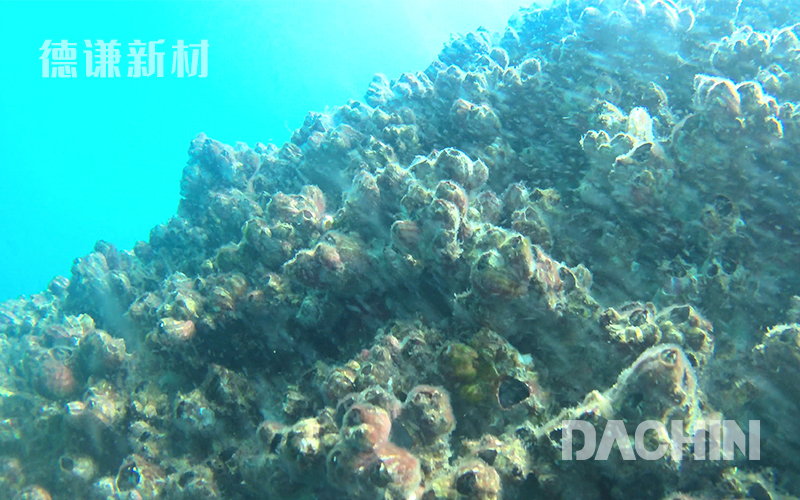

As shown in the photos, the red anti-fouling paint demonstrated good anti-fouling performance after one year, with virtually no marine life adhering to its surface, which remained in good condition. In contrast, untreated surfaces were heavily populated with algae, mussels, sponges, barnacles, and bryozoans.

The attachment of marine organisms accelerates the corrosion of steel structures, increases structural loads, and raises maintenance costs. Particularly in "wind-fish complementarity" marine ranches, it causes water pollution and can lead to oxygen depletion among farmed fish, causing death.

Based on the characteristics of marine anti-fouling, if no marine organisms grow on the facility within one year, it can be predicted that no marine organisms will adhere to the surface during the effective lifespan of the anti-fouling treatment.

COATIME®365Eco-AF Biomimetic Self-cleaning Anti-fouling Material

COATIME®365Eco-AF is a novel nano-organic silicon toughened wear-resistant anti-fouling technology. By nanomodifying organic silicon resin, it significantly enhances the toughness and wear resistance of the coating based on low surface energy interfaces. It also employs unique antibacterial technology to impart the coating with outstanding anti-marine fouling properties.

Developed by the research team at Tuchuang Times over several years, COATIME®365Eco-AF biomimetic self-cleaning anti-fouling material is a leading new type of anti-fouling coating that has been transferred to Deqian New Materials for manufacturing, promotion, and application, representing a complete industry chain collaborative innovation product.

This material is suitable for anti-fouling protection of static marine facilities: ocean aquaculture net cages, offshore wind power conductor frames, port docks, and underwater parts of bridges and piers.

Key features of COATIME®365Eco-AF biomimetic self-cleaning anti-fouling material:

- Excellent low surface energy anti-fouling: Effectively prevents barnacle attachment and is eco-friendly.

- Eco-friendly: Free from tin, DDT, and eight categories of heavy metals, the coating does not hydrolyze or release harmful substances into the ocean, with zero mortality rate in acute toxicity tests on fish.

- Long-lasting anti-fouling: Provides up to 60 months of effective anti-fouling protection.

- Outstanding flexibility and tensile strength: Enhances and toughens the coating, resistant to bending and deformation, with no cracking or peeling off after coiling.

- Room temperature curing: Easy to repair and exhibits excellent application properties.

- Smooth and flexible coating: Can withstand cleaning by underwater robots.

Static Anti-fouling is a Global Challenge

Marine anti-fouling is a global challenge, resulting in additional costs of $35 billion annually worldwide and an extra emission of 400 million tons of CO2.

Static anti-fouling differs from dynamic anti-fouling, presenting greater technical challenges than dynamic anti-fouling.

Indeed, dynamic anti-fouling benefits from the friction and shear forces of seawater, which can wash away some attached marine organisms, whereas static anti-fouling relies solely on the performance of the coating to prevent marine organism attachment.

Anti-fouling coatings are hailed as the "pearl on the crown of anti-corrosion coatings," being the most technically challenging and valuable products in the industry, which have long been monopolized by international superior foreign enterprises.

The application of Deqian New Materials on offshore wind power conductor frames helps solve the challenge of static anti-fouling, achieving domestic substitution and autonomous control, representing a new form of productive force.